What is Resistance Welding?

Resistance welding is the joining to two similar or dissimilar metals together with high current, pressure, and heat. The main benefit of the resistance welding process is that extra material is not needed to complete the weld, unlike other forms of welding. This is what makes resistance welding a very reliable, repeatable, and cost-effective welding solution.

There are several different forms of resistance welding (e.g. spot and seam, projection, flash, and upset welding) which differ primarily by the types and shapes of weld electrodes that are used to apply the pressure and conduct the current. The electrodes, typically manufactured from copper based alloys due to superior conductive properties, are cooled by water flowing through cavities inside the electrode and the other conductive tooling of the resistance welding machine.

Resistance welding machines are designed and built for a wide range of automotive, aerospace and industrial applications. Through automation, the action of these machines is highly controlled and repeatable allowing manufacturers to staff production readily.

|

|

| Resistance Spot Welding | Resistance Projection Welding |

| Resistance Spot Welding, like all Resistance Welding Processes, creates welds using heat generated by resistance to the flow of welding current between the faying surfaces, as well as force to push the workpieces together, applied over a defined period of time. Resistance Spot Welding uses the face geometries of the welding electrodes themselves to focus the welding current at the desired weld location, as well as to apply force to the workpieces. Once sufficient resistance is generated, the materials set down and combine, and a weld nugget is formed. |

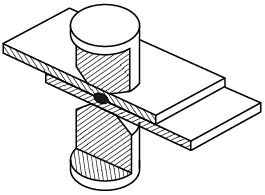

Like other Resistance Welding Processes, Projection Welding uses heat generated by resistance to the flow of welding current, as well as force to push the workpieces together, applied over a defined period of time. Projection Welding localizes the welds at predetermined points by using projections, embossments or intersections, all of which focus heat generation at the point of contact. Once the weld current generates sufficient resistance at the point of contact, the projections collapse, forming the weld nugget. Solid Projections are often used when welding fasteners to parts. Embossments are often used when joining sheet or plate material. An example of Projection Welding using material Intersections is cross-wire welding. In this case the intersection of the wires themselves localizes heat generation, and therefore resistance. The wires set-down into one another, forming a weld nugget in the process |

|

|

| Resistance Seam Welding | Resistance Upset Welding |

| Resistance Seam Welding is a subset of Resistance Spot Welding using wheel-shaped electrodes to deliver force and welding current to the parts. The difference is that the workpiece rolls between the wheel-shaped electrodes while weld current is applied. Depending on the particular weld current and weld time settings, the welds created may be overlapping, forming a complete welded seam, or may simply be individual spot welds at defined intervals. | Like other Resistance Welding Processes, Upset Welding uses heat generated by resistance to the flow of welding current, as well as force to push the workpieces together, applied over a defined period of time. While similar to Flash Welding, in Upset Welding the workpieces are already in firm contact with one another, so no flashing occurs. Pressure is applied before the current is started, and is maintained until the process is complete. |

How Resistance Welding Works:

- Pressure Application: The parts to be joined are held together under mechanical pressure by electrodes or welding tips.

- Current Passage: A high electrical current is passed through the joint area for a precisely controlled time. This current encounters resistance at the contact points between the parts and within the material itself, causing heat to be generated.

- Heat Generation: The heat generated is proportional to the square of the current, the resistance of the materials, and the time the current flows. The formula for this is Joule's Law of Heating, expressed as Q=I2⋅R⋅t , where:

- ( Q ) is the heat generated,

- ( I ) is the current,

- ( R ) is the resistance,

- ( t ) is the time.

- Welding: As the materials heat up to their melting or near-melting point, the applied pressure causes the materials to fuse together at the interface.

- Cooling: After the current is turned off, the pressure is maintained while the weld cools, forming a solid bond.

Advantages of Resistance Welding:

-

- High Speed: Resistance welding can be very fast, this makes it suitable for mass production.

- Clean: When your weld is calibrated correctly. The resistance welding produces little to no sparks, smoke, or fumes compared to arc welding.

- Consistency: The correct welding control will help provide uniform and repeatable welds if parameters are controlled appropriately.

- No Filler Material: Resistance welding does not require filler metal, reducing costs and simplifying the process.

More Questions? We're happy to help, give us a call at (937)-253-3300 .